Sme PRP, s.r.o. - líder v spracovaní ihličnatého dreva na Slovensku

700 000 m3 spracovanej guľatiny ročne, odberatelia na troch kontinentoch, pozícia popredného spracovateľa ihličnatého dreva na Slovensku s podielom na svetových trhoch a 300 kvalifikovaných zamestnancov. Posledné štvrťstoročie našej spoločnosti je bohaté na úspechy, ktoré sme dosiahli tvrdou prácou a najvyššou kvalitou produktov.

Naše služby

Spracovanie dreva

Vysoko efektívne prvotné spracovanie triedenej ihličnatej guľatiny na základné druhy výrobkov, vrátane G50 celulóznej štiepky a piliny pre výrobu EN plus A1 peliet.

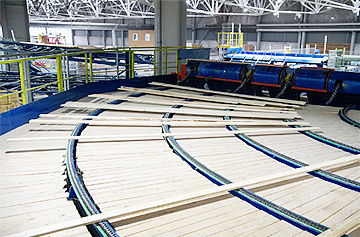

Piliarska výroba

Najmodernejšie technológie od popredných európskych výrobcov LINCK, EWD, Microtec, Vecoplan, USNR, Fromm, Framtec, Katres a Dřevostroj Čkyne.

Obchodná činnosť

Nákup ihličnatej piliarskej guľatiny zo stredoeurópskej oblasti. Predaj čerstvých alebo technicky sušených piliarskych výrobkov. Využívanie bezpečných platobných metód.

Preprava

Vlastná flotila nákladných automobilov s štandardnými plachtovými návesmi, návesmi na guľatinu a návesmi s posuvnou podlahou na prepravu sypkých materiálov.

Blog

Každému obchodnému partnerovi – dodávateľovi guľatiny daruje spracovateľ dreva firma PRP s.r.o. Tomášovce pri Lučenci za každý dodaný kubík dreva jednu sadenicu. Netradičná odmena je zastrešená

...Spoločnosť PRP s r.o. v Tomášovciach pri Lučenci zamestnáva viac ako 300 kvalifikovaných zamestnancov, spracováva ročne vyše 700 000 m3 ihličnatej guľatiny a jej obchodní partneri sú na štyroch

...